Upgrading My Camper Van Electrical System to Lithium Batteries

Once you go lithium, you'll never go back!

I can’t believe I waited so long to replace my camper van’s busted-ass AGM batteries with shiny, powerful lithium ones. That single upgrade greatly improved our van travel experience.

Prior to the upgrade, our old batteries from the initial build in 2013 wheezed like a smoker's lungs. They tried hard, but couldn't get the job done.

The batteries had juice to power basic items in the van like laptops, roof fan, heater, fridge. But the overall capacity and voltage output had decreased to borderline unusable for any high-current load like a countertop water boiler. Which meant no quick morning coffee for Chelsea, which meant OMG FIX THIS IMMEDIATELY.

Also, the tiny microwave I installed last summer could only heat up food while we were driving or our inverter threw an error. People, I’m talking about an EXTREME inconvenience. I choose to sleep in a van versus a tent for comfort, dammit! I reserve sleeping on the ground for bikepacking.

(In defense of our old Fullriver batteries, we did use them five years past their typical use date. They were champions in their day.)

Suffice it to say that anyone considering replacing their old AGM (absorbent glass-mat) or FLA (flooded lead acid) batteries will see an incredible improvement in their electrical systems. Here are the details of my upgrade.

Reasons lithium batteries kick butt

Lithium batteries maintain their voltage output down to 10% of their capacity. Compared to AGM or lead acid, which are almost useless below 50%, you get way more useable power even with the same amp-hour capacity.

Lithium batteries weigh about half what AGM batteries do. My ~13"x7"x9" batteries are only 31 pounds each. Especially for big battery banks, that's a lot less weight.

Lithium batteries have a faster “absorption phase,” which means they charge faster. (It seems like 3-4x faster than AGM is what most companies claim.) Many people online mention how quickly their system charges while driving or via solar power. What’s not to like?

Downsides to lithium batteries

Ok, fine, there are some downsides to lithium. It’s not all sunshine and peanuts.

Lithium batteries can’t charge in below-freezing temperatures. Since my old AGM batteries were mounted underneath the van, I needed to relocate them inside. (Or build a heated box for the new batteries or buy fancy, mega-expensive batteries. Um, no thanks.)

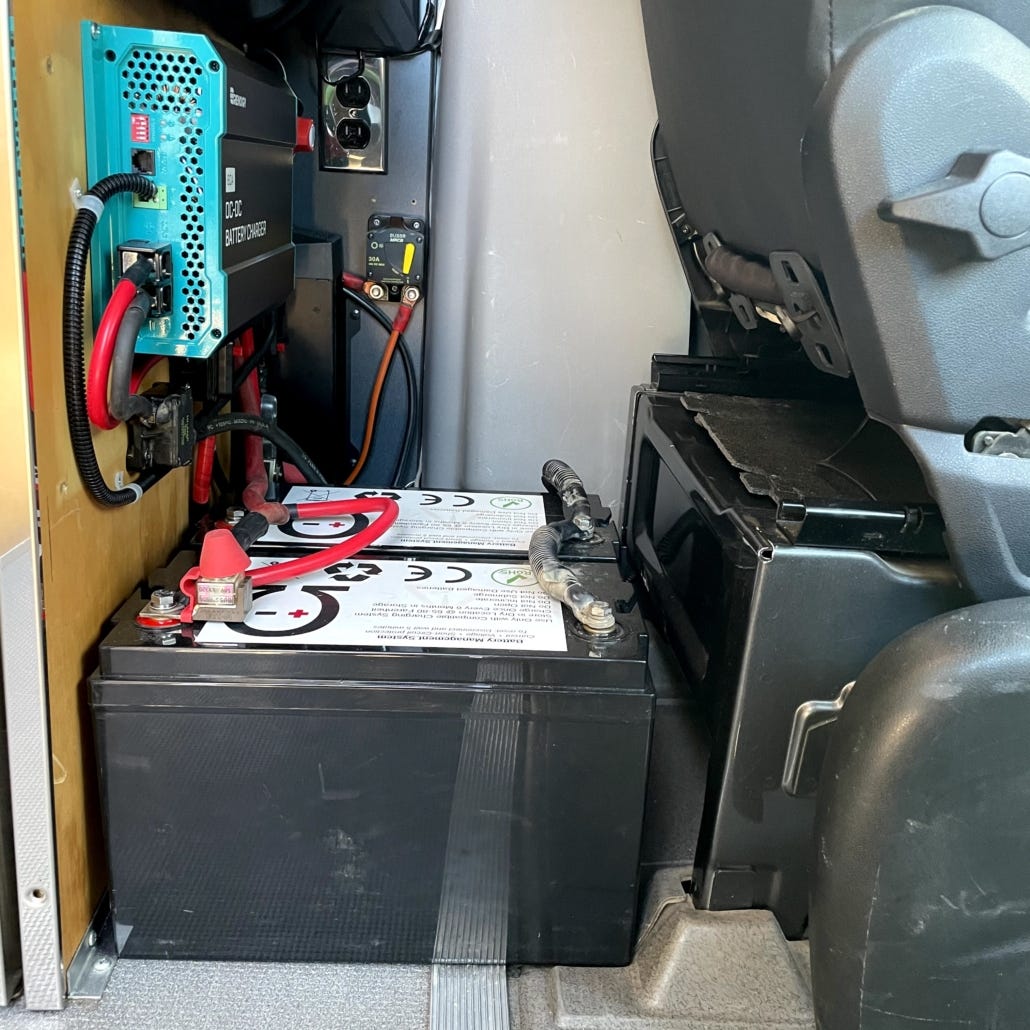

I solved this by moving our gray water tank underneath the van (and upping the volume by 6x) and putting the batteries behind the driver’s seat in the van. Overall, I think this setup makes more sense anyway.

Other considerations:

Yes, lithium batteries are more expensive upfront. You can buy 300 Ah of AGM batteries for about half the cost of lithium. However, if you take the life-cycle cost into account (i.e. pick a time span and compare batteries), lithium eventually ends up being cheaper.

At 3,000 lifetime charge cycles for the Ohmmu batteries, that’s 10 years of use at 300 nights per year, or roughly 3-4x more cycles than you’ll get for AGM batteries. Given the better performance of lithium batteries, I think it’s worth it if you can afford the upfront cost. If you're only looking to use your batteries for a weekend rig or want to save cash, it's worth reading through this extensive vanconverts.com post about AGM vs. lithium.

By the way, dig these kinds of posts? Sign up for the free 2x/month Traipsing About newsletter for van talk and outdoor adventures.

How I chose my new lithium batteries

For my new lithium batteries, I researched the Internets and ultimately chose a company called Ohmmu. There are many van battery options out there, but Ohmmu delivers more value than its competition.

From what I saw, Ohmmu's lithium iron phosphate (LiFePO4) batteries pack more power into a smaller, lighter package. The company uses prismatic cells vs. cylindrical ones in most lithium batteries. That means more active cells = less wasted space = more capacity and longer lifespans. (For engineering dorks like me, I put more details on the tech at the end of this post.)

Batteries are a commodity and the most important factors are cost, capacity and size. If cost and size are the same, then finding the one with the most capacity is what matters.

For example, Battleborn and RELiON batteries are a similar cost, weight and size as Ohmmu, but only provide 100Ah per battery vs. Ohmmu’s 150Ah. At $~900-$1,000 each for lithium batteries, that means it costs 50% more to get the exact same capacity, not to mention needing to find space for another battery. No thanks.

Full disclosure: Ohmmu sent me two batteries for free when I reached out, though I would have bought them anyway since they're a great value. I don't make anything if you buy their batteries.

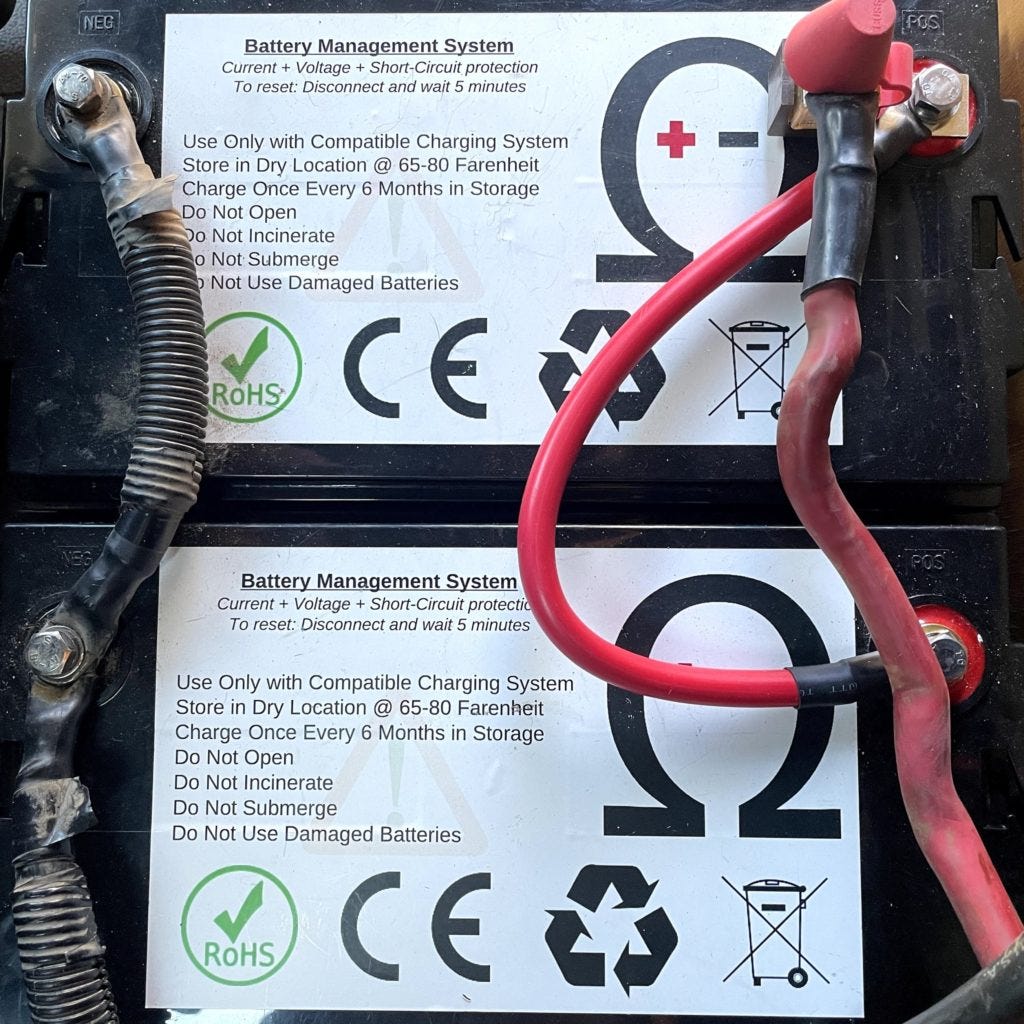

For my install, I went with two 150Ah Ohmmu batteries, a total of 300 Ah of power. That's 1.5x what we had before, plus we can drain the system to 10% versus the 50% with AGM. Let's skip the math and call it what it is: MORE BETTER.

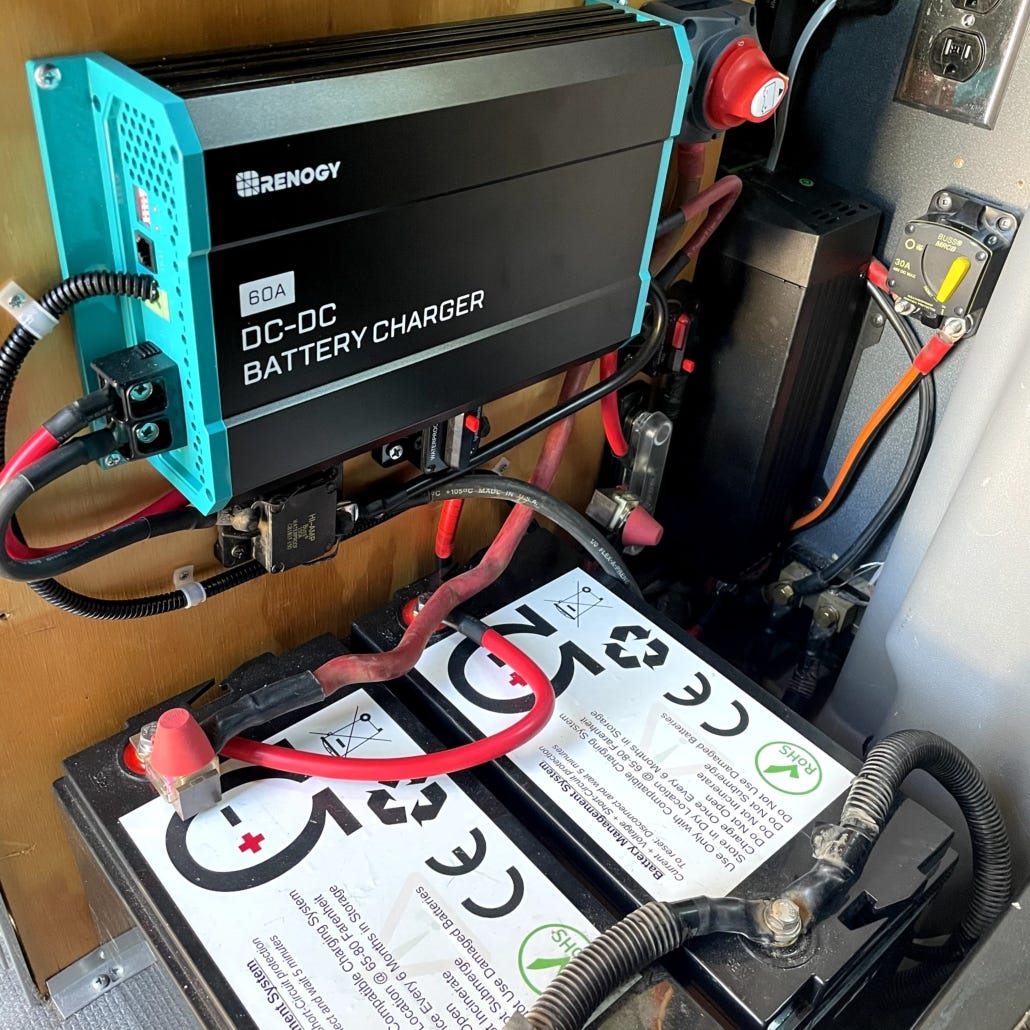

My battery installation

Other than the pain of scrambling around beneath the van getting chunks of dirt in my eyes, rewiring my new batteries wasn’t difficult. The only complicating factor was that my new Ohmmu lithium batteries are 12V and my Fullriver AGM’s were 6V.

Since our van is designed around a 12V system, I rewired things in parallel vs. the old setup with two 6V batteries in series. If you’re thinking, “What the hell does that mean,” please consider paying someone to install your new batteries.

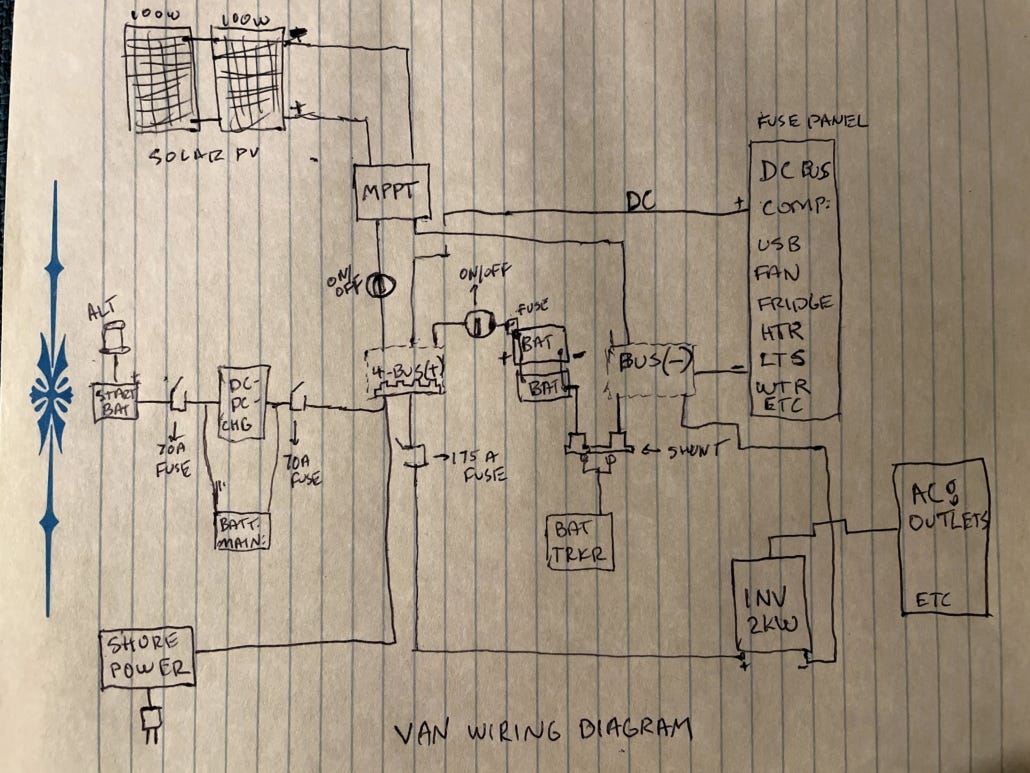

My hand-drawn diagram, super sick wiring diagram is below. FYI, I used 4AWG wire for the charger and 1AWG for battery connections, but yours will vary based on your system's needs. FarOutRide’s fantastic electrical system writeup is excellent and can walk you through details if you aren't confident about electrical calcs. (I adopted their idea of extra fuses on the batteries, thanks y'all.)

Selecting a DC-DC Charger

One other significant difference with lithium batteries is that charging them with excess vehicle alternator current isn’t as simple. Rather than a battery separator, lithium needs a DC-DC charger to keep the battery in good shape. I think it’s possible to run a battery separator between the alternator and the DC charger, but I didn’t see any benefit to it and removed mine.

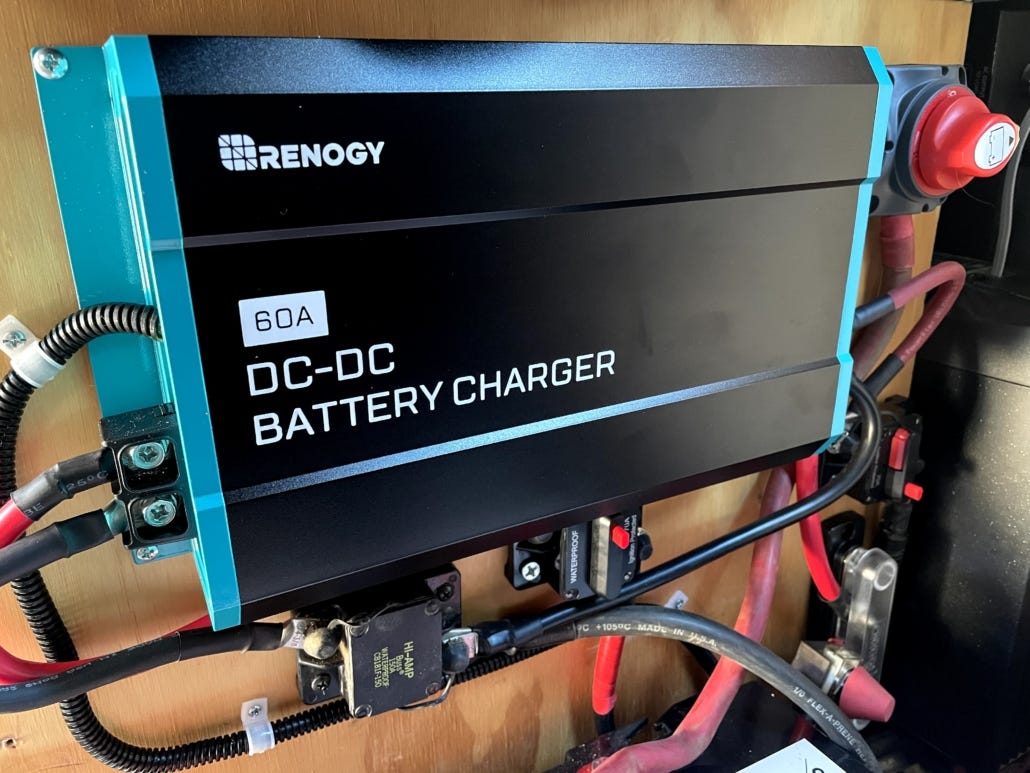

After reading about various options, I picked up a Renogy 60 amp DC-DC charger (disclosure: also comped for free). There are more expensive, fancier options on the market, but in my mind, Renogy provides a solid product that does exactly what I need it to: put current into my batteries with no fuss. Many camper vans successfully run their chargers, so I expect mine to work well.

The 60 amp rating means that when I drive for an hour, my batteries receive 60 Amp-hours, 1/5th of my 300 Ah capacity. Beyond 60A, an upgraded, separate alternator is needed (no thanks).

Even with batteries inside, you may want to pick up a temperature sensor (here is Renogy's) and connect it to your DC-DC charger to make sure you aren't putting too much current into your batteries. Jump to low temp charging below for the settings I'm using.

Note: for the DIP switch settings, I used the following: 1-OFF, 2-ON, 3-ON, 4-ON, 5-OFF. This forum post was useful for sorting this out, but it will depend on your specific batteries.

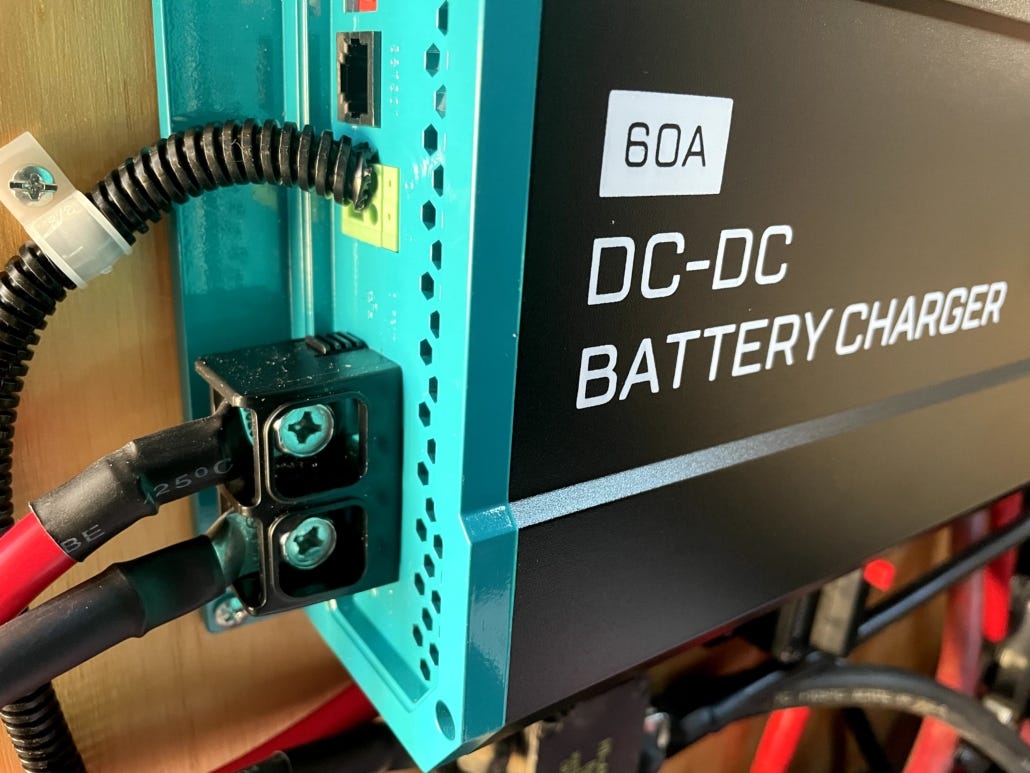

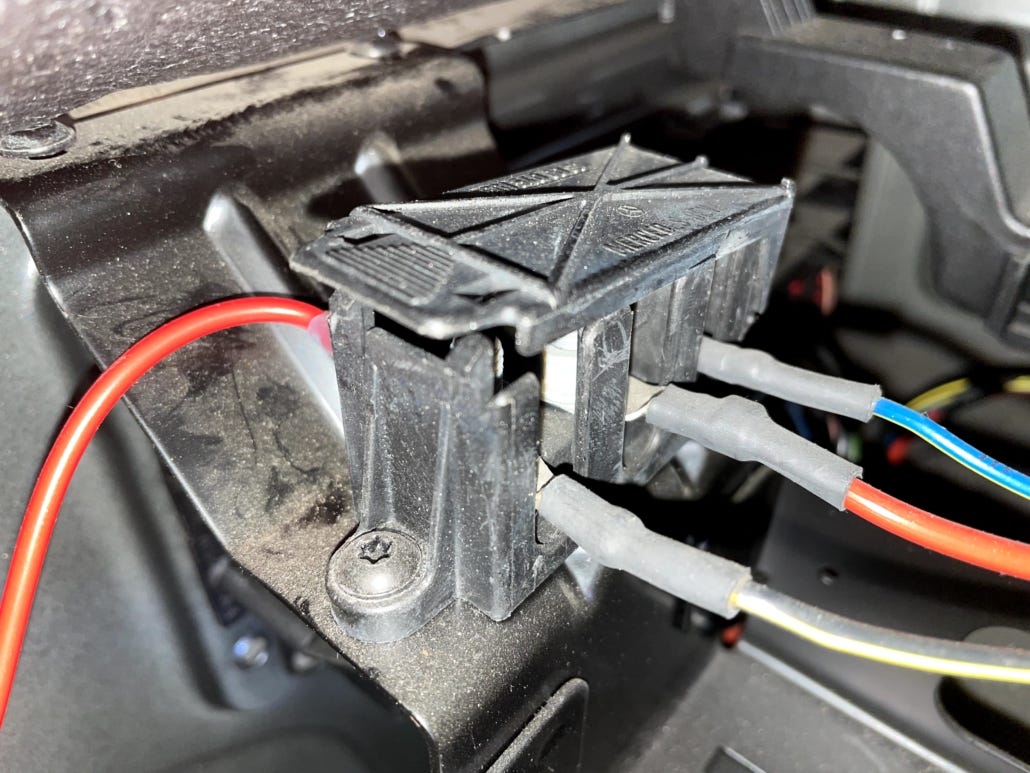

Dealing with the D+ signal wire

One thing that initially seemed complicated with Renogy was the “D+ signal wire,” which simply tells the charger to turn on only when the vehicle is running. Luckily, underneath the driver’s seat of the Sprinter is a wiring bank with a D+ terminal on it.

Rather than needing to tear apart the dashboard, I simply ran 16AWG wire between that terminal and Renogy’s DC-DC charger and WOOT, everything worked. (Is there anything better than a solution that’s easier than expected versus, you know, the usual?)

Overall, wiring the install proved quite easy with pre-cut wires like these. Sure, you can buy crimpers and make your own, but why bother for such a small project?

Just one thing left to do: reprogram my MPPT controller so my solar panels don’t turn my new lithium batteries into a nuclear bomb. (Don’t worry, that’s not what happens if you screw up.)

Reprogramming the MPPT controller

Lithium batteries have a major difference from other batteries: they don’t use an “equalization phase.” I won’t go into details here about why, but make sure to disable equalization on your MPPT controller.

My MPPT controller from 2013, a Blue Sky 2512i(X), isn’t fancy. I can’t control it with my phone and it doesn’t wash my dishes, but it does what it needs to. Luckily, by reading through the manual (how fun), I figured out how to set things to what Ohmmu specifies for their batteries.

Disabling equalization was simply a flip of a DIP switch on my MPPT, whereas the other settings were easily changed from a settings menu. Your MPPT manual has the answers.

Here are the settings I used for my Ohmmu batteries. Make sure to check your specific battery charger requirements!

Charger settings:

Absorption 14.4V

Float 13.5V

No Equalization

Charging Your Batteries in Low Temperatures

When charging with solar, it depends on your system’s output. For 0-32F, Ohmmu batteries can handle 20A. Since our 200 watts of solar generates a max of 200W/12V=16.7A in ideal conditions, there’s no way the current will exceed 20A. (Deep-dive into why here if you're interested.)

Even at -20F, the batteries can handle 10A, which is still likely more than our solar panel output given the low angle of the sun in coldest part of the day (i.e. the morning). I'm testing this out to see if I need a temperature sensor like this one for my Blue Sky MPPT controller.

That left the most heart-wrenching part of any project: turning on the power. Picture the scene from Ocean’s 11 when the guy turns and covers his junk before he kills the power in Vegas.

The verdict: Lithium batteries kicks ass

No melted wires or explosions, folks! The system worked first go.

The results: our 750W microwave works perfectly, our 1000W water boiler cranks out coffee water, and the batteries charge far faster than our AGM batteries did. Unless we park the van in a cave for a week of spelunking, I think I’ve solved our power issues.

We couldn’t be happier with the decision to upgrade from AGM batteries to lithium. With the extra juice, we've added a small Instant Pot and microwave to our van to bring some comforts of home with us on the road. As any van lifer will tell you, it's the small things when you're traveling.

I'm looking forward to many years of hot coffee for Chelsea in the morning and quick hot meals for me after a mountain bike ride!

Post-script: All the obsessive details about Ohmmu batteries

I was curious about why Ohmmu’s lithium batteries have 1.5x more capacity than the competition, so I emailed the company. Below is the response from Sean, their founder:

Caveat: this section is for someone looking for all the battery details. If you simply want batteries that work, just order some and be happy. Otherwise, dig in.

From Ohmmu:

Our biggest points of emphasis are capacity (Ah) and our use of prismatic cells (rather than cylindrical).

The reason these are critical:

Capacity is the single most relevant and important characteristic of any battery. The greater capacity of the battery indicates a larger surface area for chemical reactions to occur inside of the battery.

With the larger surface area of prismatic cells, the stressors at any given point are decreased and the "work" the battery is performing is distributed across a larger area. The result of this is not only a longer run-time per charge, but more critically, it relieves the stress of use over time and leads to much longer lifespans.The other great thing about having the most capacity possible is that you can better manage your energy storage. You don't need to fully charge or fully deplete the battery, but can charge to just 80-90% and discharge to 10-20%, providing additional stress relief for your battery.

The biggest stressors on a battery occur when it is fully charged or fully discharged since the chemical reactions that occur become overly-saturated or overly-desaturated and result in small but permanent capacity losses over time.

Getting deep in the technical weeds, this is why prismatic is better than cylindrical:

Our batteries are a sealed system. There is no coolant or air flow occurring through the battery pack inside of the plastic case. This means we rely exclusively on conduction to evenly distribute and dissipate the heat that builds up inside of the cells.

Our prismatic cell packaging allows for superior conduction of heat across the battery pack since (unlike cylinders), we can package our cells so the majority of the cell surface area is in direct contact with its neighboring cells.

Additionally, we can package more active material inside of our batteries because less space is wasted (less air) and of course this additional active material leads to more capacity and longer lifespans.